Months ago we talked about what billiard balls are made of, and today it’s the turn for the billiard cues, the extension of our arms. We are used to seeing them clean and shiny, but behind those perfect designs, manufacturing processes and a variety of materials, especially wood, essential for good a play, are hiding. It's time to discover them.

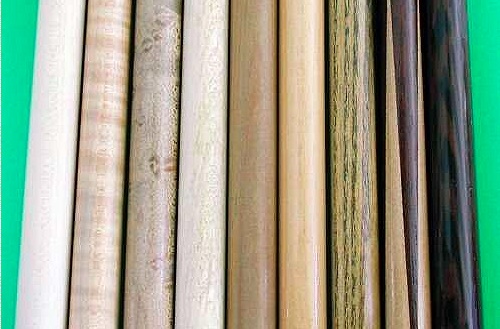

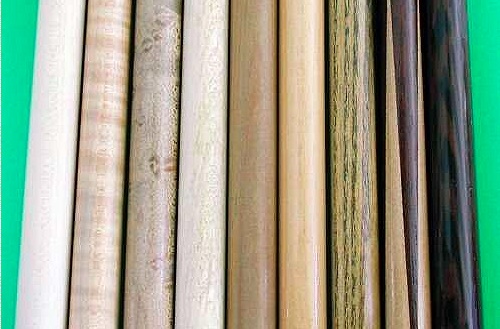

The two kinds of wood most used in the manufacture of billiard cues are Maple and Ash. The reason is simple: they absorb shocks well, are very rigid and very resistant. If the maple is used more for Pool cues, ash, more expensive, is more typical of good Snooker cues.

However, there are a dozens of different woods for making cues, among which ebony, olives, amaranth or hornbeam are some of the most used. And there are even other materials beyond wood, such as aluminum or fiber, very popular in Cuetec cues.

In the following video you will discover how a Falcon cue is made from rectangular wooden block unit it’s finally finished:

The cues are made by parts to reduce the risk of breakage and to assemble it easier and make it more comfortable to transport. Thus, for each part different types of wood are used: for example, maple for the shaft and the base of the butt, and black ebony for the inlays. The more detailed and accurate are these designs, which sometimes are made with precious stones, the more expensive the cue is. For the handle (grip), usually wood with leather or nylon thread is covered for the player to feel more comfortable during the shooting.

How are billiard cues inside? Surely you've ever been curious about whether they are solid or otherwise are hollow. Most of them respond to the first option but there are also carrying a cylinder of carbon fiber inside to be more strengthened.

There are also laminated shafts: inside are cut into sheets and grouted, so that gain they gain resistance and deflection is reduced when playing with effects. Here's the example of Predator:

A pool cue must be completely straight, must have the weight distributed and must not deform over time. So manufacture is a complicated task that requires much time and many processes: select wood, convert the block cylinder, lower it to the correct diameter, working the shaft and the butt separately, make inlays, the joint, cap and tip, and finally polishing and varnishing. It’s an art, although machines increasingly accelerate processes.

To end this tour of the anatomy of a cue, do not miss the video by Ronnie O'Sullivan visiting the temple of Parris Cues, one of the most famous and recognized brands that manufactures Snooker cues: